LIVE IN OMAHA.

When you live in Omaha, you canstand-up and stand-out.

More Than a Great Place to Live and Work. Omaha is a Great Place to Be Alive.

When you live in Omaha, you can stand-up and stand-out. With a diverse business community and a bustling arts-and-culture scene, Omaha is potential unleashed.

Whether you’re thinking of relocating to Omaha or moving back after time away, we’re here to help connect you to the people and resources that will make Omaha your home.

Below you’ll find links to read the We Don’t Coast magazine online, a few of Omaha’s “best city” rankings and ways to connect with a Local Omahan to get all your questions answered.

We recommend you start by downloading our Omaha Mover’s Guide. It contains information about which neighborhood would be right for you, who to call for utility hookups and what you can expect to pay for a home. Our low cost of living and high quality of life make it easy to see why nearly 1 million people live in Omaha and the surrounding area.

Ignite Your Career in Omaha.

Companies of all sizes — startups to Fortune 500s — choose Omaha. Find where you fit and ignite your career. Here, we embrace entrepreneurs, cultivate innovation and let imagination run free.

See Local Job Boards.

Attend Networking Events.

Connect with Young Professionals.

Our Young Professionals offers lots of ways to connect throughout the year.

Omaha by the Numbers.

Omaha is a city where you can live big for less. Here, you can work to live — not live to work.

Number of people living in Omaha: 990,402

Cost of living in Omaha: 6.4% below the national average

Median home price: $220,600

Average one-bedroom apartment rent: $838

Unemployment rate: 2.8% (as of July 2021)

Average commute is 20.5 minutes

Wondering Where to Live in Omaha?

It’s amazing how many personalities can thrive in one family tree. Omaha is a lot like that – a mix of communities, each with its own personality, comprising one vibrant metropolitan area. Tour our diverse blend of neighborhoods and districts – urban, suburban and rural – and you’ll find an expansive list of reasons why we love where we live.

Don’t Just Take Our Word For It.

#4

City for First-Time Homebuyers

— SmartAsset, 2021

#14

Most Affordable Places to Live in the U.S.

— U.S. News & World Report, 2021

#9

Best Places to Raise a Family

— WalletHub, 2021

Want to Know What it’s Like to Live in Omaha? Ask a Local.

If you’re looking to move to Omaha–and you want to know what it’s like to live here–there’s no better way to find out than to ask a local. Several local Omahans are ready with answers to any of your questions.

Want to know about the arts scene? The foodie culture? Where to find makers? The best cup of coffee or local donut joint? Our locals can help.

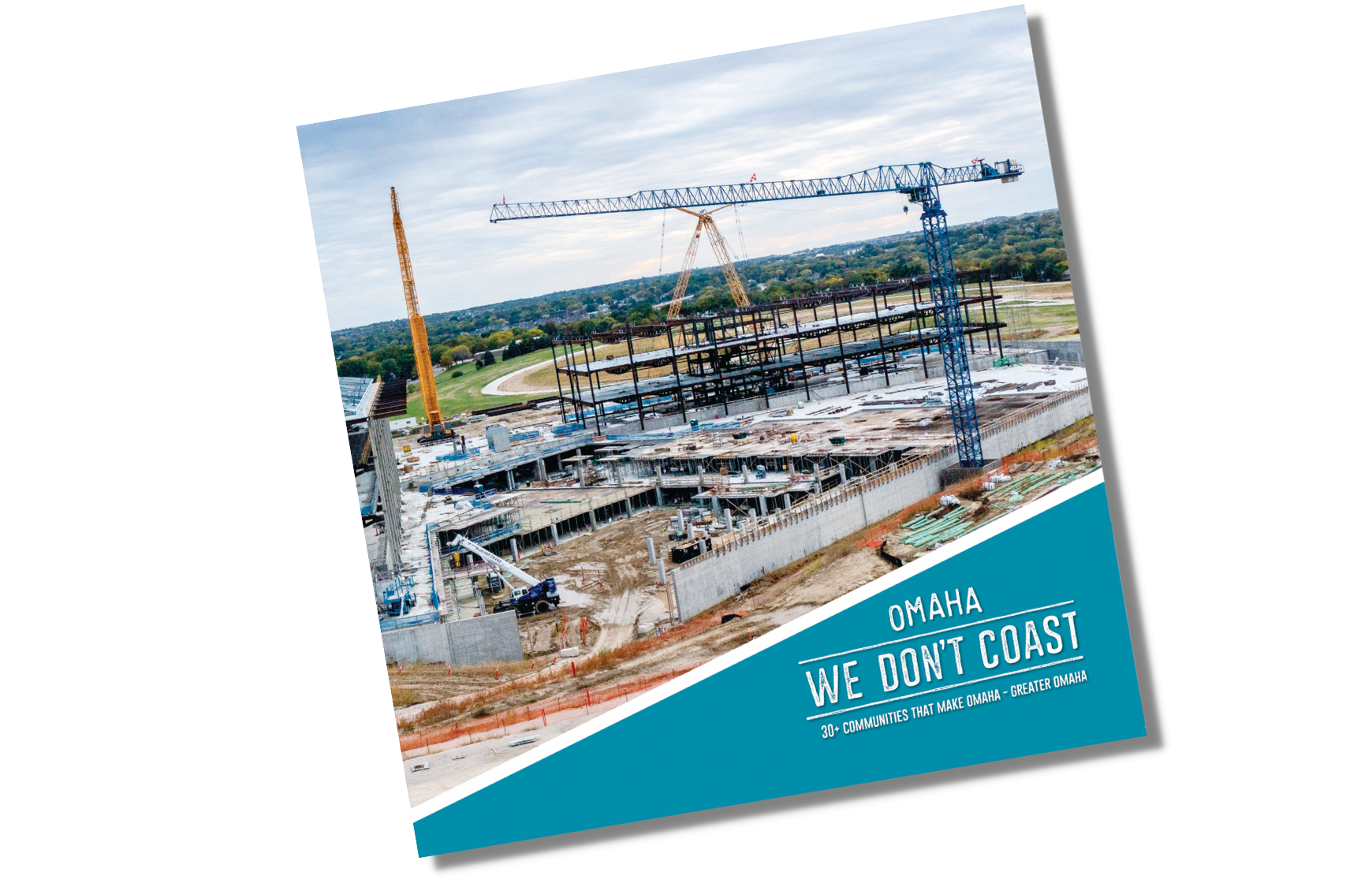

We Don’t Coast Magazine

Take a closer look at Omaha and all it has to offer in We Don’t Coast Magazine. You’ll see that Omaha is more than you imagined and exactly what you want.

There’s a little bit of #WeDontCoast in each of us. It’s how we work and live. It’s why we call Omaha home.

Hear Local Stories.

Lives Podcast features conversations with fascinating people sharing their personal stories and their impact on the Greater Omaha community.

Fresh voices and diverse perspectives on culture, community, business and more brought to you in this conversation hosted by Stuart Chittenden.

Get to Know Omaha at Intro.

Join us at Intro, where we welcome new residents, students and visitors of Omaha. It’s a chance to get to know the city and everything our community has to offer. You’ll make some new friends, share stories and hear recommendations of the best ’things to do” in Omaha or to discover new favorites.

Get Our Free Mover's Guide.

Contains information about Omaha’s cost of living, neighborhoods, quality of life, school districts and so much more.